In today’s rapidly evolving technological landscape, the advent of cutting-edge machinery has transformed various industries. One such innovation that is revolutionizing manufacturing processes is the 5 axis milling machine. With its advanced capabilities and precision, this machine has become a game-changer in the field of machining.

The Power of 5 Axis Milling Machine

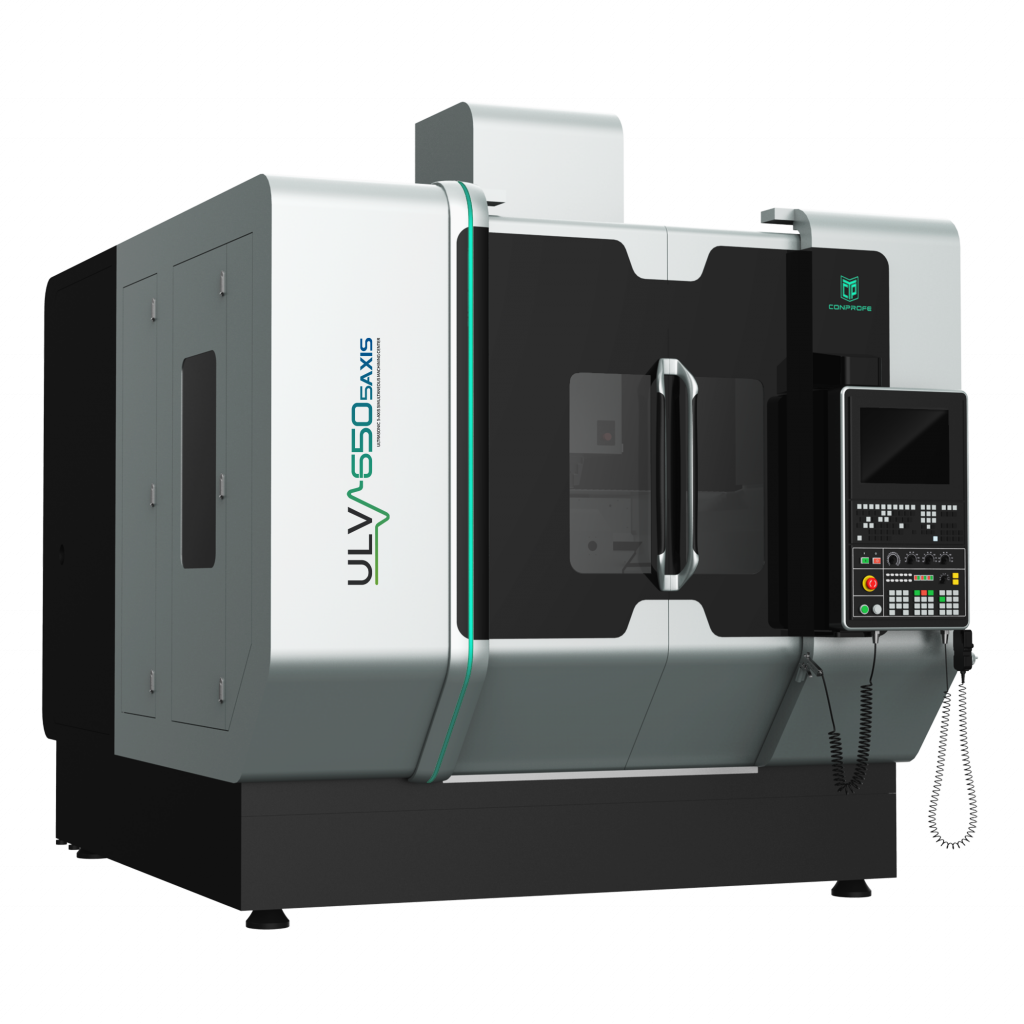

The 5 axis milling machine offers unparalleled versatility and efficiency compared to traditional machining methods. Unlike conventional machines that operate on three axes (X, Y, and Z), this state-of-the-art equipment adds two additional rotational axes (A and B). This enables it to perform complex operations from multiple angles without requiring repositioning or resetting the workpiece.

With its ability to rotate at different angles simultaneously, the 5 axis milling machine can produce intricate designs with exceptional accuracy. It allows manufacturers to create highly precise components for various industries such as aerospace, automotive, medical devices, and more.

Elevating Precision with Conprofe Ultrasonic Technology

One notable player in the realm of ultrasonic technology is Conprofe Ultrasonic. Their innovative solutions have further enhanced the capabilities of 5 axis milling machines by introducing ultrasonic vibration-assisted machining techniques.

This groundbreaking approach combines high-frequency vibrations with traditional cutting methods to achieve superior surface finishes while reducing tool wear. The integration of Conprofe Ultrasonic technology into 5 axis milling machines ensures higher productivity and improved quality in manufacturing processes.

The Advantages of 5 Axis Machining

When it comes to complex part production or prototyping tasks, nothing beats the advantages offered by 5 axis machining. By enabling simultaneous multi-axis movements during operation, this technique eliminates time-consuming setups required by traditional machining methods.

Moreover, 5 axis machining allows for the production of intricate geometries that would be otherwise impossible to achieve with conventional machines. It offers increased flexibility and efficiency, resulting in reduced production time and costs while maintaining exceptional precision.

The Future of Manufacturing

-1-1024x919.png)

The integration of 5 axis milling machines into manufacturing processes has undoubtedly transformed the industry’s landscape. With its unparalleled capabilities, this cutting-edge technology opens up new possibilities for creating complex components with utmost precision.

As advancements continue to push the boundaries of what is possible, it is clear that 5 axis milling machines will play a pivotal role in shaping the future of manufacturing. From aerospace engineering to medical advancements, this innovative machinery paves the way for endless opportunities and individualized services tailored to clients’ specific needs.